Rework is one of the largest hidden expenses in construction with costs exceeding 11% of total project budgets, according to a 2023 international survey1. Even when budgets include a rework allowance, these unplanned expenses routinely exceed projections, eroding already-thin margins.

Project teams can now significantly reduce or eliminate rework by taking a proactive approach using robotic automation and AI. This article examines what rework is, its impact on ROI, its root causes, and how innovative new technologies can offer solutions.

What is Rework in Construction?

In construction, rework refers to correcting or repeating a task or tasks due to errors, omissions, or other deviations from the project plans or specifications. Rework can have several causes and ranges from a small amount of work to something major.

For example, if attachment points for storefront glazing aren’t marked correctly, the glazing will need to be removed, the brackets moved to the correct location, and the glazing reinstalled. Another example could involve installing material that meets the project specifications but is found to not meet the owner’s quality specifications when installed.

Large vertical construction projects are particularly vulnerable to rework, as a small mistake on one floor can cascade to the floors above and below, multiplying the scope of the rework and adding both cost and time to the schedule.

The Cost of Rework and Impact on ROI

Rework isn’t an occasional problem, in fact rework occurs on nearly every construction project. Research from the Construction Industry Institute found that rework can affect up to 30% of construction activities on a given project, with total rework costs typically ranging from 5-20% of total contract value.

The costs of rework impact contractor profitability far beyond the obvious material and labor expenses. Contractors may recover some direct costs from owners, but the indirect impact (schedule delays, extended equipment rentals, and manpower disruptions) typically falls squarely on their bottom line.

The opportunity cost compounds these losses. Workers tied to rework can’t move to new projects, limiting a contractor’s ability to take on additional work and generate new revenue.

Delays also mean delayed revenue, which can have a disastrous effect on cash flow. A project that’s 20% over budget due to rework can quickly erode already-thin profit margins, especially when payment is tied to milestones or completion.

The nature of contractor relationships means all this flows downstream to trade contractors and material vendors, affecting the entire project team and often straining long-term partnerships.

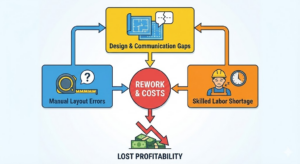

What are the Causes of Rework?

Understanding the root causes of rework is essential to preventing it. While some causes are obvious, others are systemic issues that have plagued the industry for decades.

The Push for Prefabrication and Tighter Tolerances

One of the most significant (and often underestimated) drivers of modern rework stems from the industry’s evolution toward prefabrication.

The industry shift from in-situ construction (building on-site) to prefabrication (assembling on-site) has introduced a new challenge: the collision of manufacturing precision with construction reality.

- In-Situ vs. Prefab Logic. Previously, trades could cut materials to fit actual site conditions through field-fitting. With prefabrication, components are built off-site to a theoretical model. If site conditions deviate even slightly from the model, prefabricated parts (pipe spools, wall panels, duct runs) will not fit, requiring expensive modifications or re-ordering.

- The “Datum” Problem. In small-scale manufacturing like electronics, the entire workpiece fits inside a machine that establishes a perfect “zero point” (datum) for every operation. In industries like construction and shipbuilding, there is no single, stable reference point. The work area is often shifting dirt, curing concrete, or steel expanding in the sun. Without a global datum, maintaining tight tolerances over long distances creates an exponential error curve.

- Scale Amplifies the Challenge. Coordination is difficult even on small assemblies. Tesla, for example, famously struggled with sheet metal panel alignment on the Model 3, despite the vehicle being only ~15 feet long and built by robots. When you scale that coordination challenge up to a facility that is 1,000+ feet long, the margin for error effectively vanishes.

The following table illustrates the disparity in allowable error relative to total object size. While the absolute tolerance in construction (1.5mm) seems similar to automotive, maintaining it across a massive span (1,200 ft) makes it orders of magnitude more difficult relative to the scale of the work.

| Industry | Object Scale | Critical Feature | Typical Tolerance | Error Ratio (PPM) 2 |

| Electronics | ~0.5 ft (Phone/Tablet) | Hall Sensor Placement | +/- 0.1 mm | ~660 PPM |

| Automotive | ~15 ft (Tesla Model 3) | Panel Gap Spacing | +/- 1.5 mm | ~320 PPM |

| Construction | 1,200 ft (Industrial Floor) | Prefab Alignment | +/- 1.5 mm | ~4 PPM |

As the data shows, asking a construction team to hold a +/- 1.5mm tolerance across a 1,200 ft span is statistically harder than placing a micro-sensor in an iPad. This mismatch between required precision (for prefab) and achievable precision (on-site) is a massive generator of rework.

Traditional Causes of Rework

Beyond the challenges of prefabrication, several longstanding issues continue to drive rework across the industry.

Layout Error

Relying on humans to make measurements can result in inconsistencies, even with specialized training. Small errors quickly add up in large projects and can significantly affect downstream work. Incorrect placement of layout points is a top driver of cascading errors. Adding to the cost, layout errors often go undetected until after materials are installed. Teams end up paying twice – first for removing incorrect work and making corrections, then for redoing the installation.

Design Errors and Changes

In fast-track projects especially, incomplete or unclear plans and drawings can lead to mistakes. With little time for an extensive documentation review, teams rely on plans with missing details and incomplete or missing specifications.

The presence of multiple trades increases the likelihood of overlapping or conflicting designs when coordination takes a back seat to speed and production. Design changes made late in the process can create mismatches between what’s drawn and what’s already built.

Communication Breakdown

Even with the latest technology, communication on a project can still break down. When the office and field aren’t in sync, or when trades don’t coordinate with each other, problems invariably follow. Poor communication is one of the top drivers of rework, affecting everyone on the job.

Labor Issues

The ongoing struggle to attract skilled workers to the industry directly contributes to increased rework. Contractors are often forced to send inexperienced, untrained workers to job sites just to meet manpower requirements, leading to more mistakes. Even experienced workers aren’t immune. Repetitive tasks like drilling or marking layout points lead to physical and mental fatigue, increasing error rates across all skill levels.

Lack of Quality Control

Often, verification and quality control get lost in the rush to complete projects on time and on budget, oftentimes with mistakes caught after the work is complete, instead of as they’re happening.

When quality checks are made, human inspectors can miss deviations that aren’t visually obvious but fall outside the set tolerances.

Tolerance Stack-up

Rework often occurs not because a single component is “wrong,” but because multiple acceptable deviations combine to create a failure. This is known as Tolerance Stack-up.

- The “Perfect World” Fallacy. BIM models and CAD drawings typically assume “nominal” dimensions (e.g., a beam is exactly 10.000 feet long). In reality, every material has a manufacturing tolerance. When designers do not account for these variations accumulating, the final assembly fails.

- The Chain of Deviation. In construction, stack-up is distinctively linear and unforgiving.

- Step 1: The concrete slab is poured and is 3mm high (within tolerance).

- Step 2: The steel anchor bolts are set 3mm off-center (within tolerance).

- Step 3: The steel column has a camber/sweep of 3mm (within tolerance).

- Result: By the time the prefabricated glass façade arrives, the mounting point is now 9mm out of position. Since the façade clips only have 5mm of adjustability, the panel cannot be installed.

- The “No-Fault” Rework Loop. Tolerance stack-up creates a frustrating scenario where every individual trade can prove their work was “within spec,” yet the building still doesn’t fit together. This leads to costly disputes, on-site fabrication (cutting/welding), and schedule delays while teams argue over who is responsible for the gap.

Poor Data Visibility and Project Coordination

Disconnected teams and communication systems make it difficult to track project changes. Without real-time information on a common platform, errors often aren’t noticed until they’ve compounded, increasing the cost to correct them.

Manual data collection also creates gaps in as-built documentation, with teams often waiting until the end of the project to update plans, by which time critical information may be lost or forgotten.

How to Reduce Rework by Leveraging AI and Construction Robotics

The causes of rework share a common thread–they all stem from the limitations of manual processes in an industry demanding manufacturing-level precision at an unprecedented scale. AI and robotics directly address these root causes by bringing factory accuracy to the job site.

Solving the “Datum Problem” at Scale

Robotic systems overcome the difficulty of maintaining tight tolerances (e.g., +/- 1.5mm) across massive spans (1,200+ ft) where manual datum points drift over time and distance.

These systems establish a precise, global coordinate network that persists throughout the project, ensuring the entire work area remains accurate from foundation to finish. By replacing shifting manual reference points with digital precision, robotics bring the same level of control to construction that a “zero point” provides in manufacturing, solving one of the industry’s most fundamental challenges.

Synchronizing Off-Site Prefab with On-Site Reality

Robotic automation brings factory-level precision to the construction site, ensuring that field conditions match the theoretical models used for prefabrication. This eliminates the need for costly “field-fit” adjustments like cutting and welding by ensuring that on-site installation points align perfectly with off-site assemblies.

The result is a dramatic reduction in installation failures when high-tolerance components (such as glazing systems or modular MEP assemblies) arrive on site, eliminating one of the largest sources of modern rework.

Precision Layout and Measurement

Automated layout systems eliminate manual interpretation errors by translating digital plans directly to physical field coordinates with millimeter-level accuracy. For a deeper dive into this capability, see our Guide to Automating Construction Layout.

This level of precision ensures strict adherence to tolerances and dramatically improves the “Parts Per Million” accuracy ratio required for modern, complex facilities—transforming what was statistically nearly impossible into a reliable, repeatable process.

Mitigating Tolerance Stack-up

Robotic execution, such as automated drilling, hits nominal dimensions consistently, breaking the “chain of deviation” that causes tolerance stack-up failures. By preventing the accumulation of small, individually acceptable errors that combine to cause late-stage assembly failures, robotics ensure that hole locations, angles, and depths remain precise.

This prevents the downstream misalignment issues that plague structural and MEP connections, eliminating the frustrating “no-fault” rework loop where every trade was within spec but the building still doesn’t fit together.

Real-Time Quality Assurance and Verification

Robotic systems shift quality control from a reactive post-mortem to a proactive, real-time process. Robots capture immediate as-built data during installation, flagging deviations before they are covered up or compounded by subsequent trades.

AI analytics take this further by identifying patterns in layout or installation data, allowing teams to predict and prevent future rework hotspots and address potential issues before they become costly problems.

Reducing Fatigue-Induced Variance

Automation standardizes execution quality by removing physical strain and fatigue as variables in accuracy. Whether it’s the first hole drilled in the morning or the thousandth at the end of a shift, robotic systems deliver repeatable, precise results regardless of labor shortages or crew experience levels.

This consistency is particularly valuable given the industry’s ongoing skilled labor shortages, ensuring quality work even when experienced workers are in short supply.

Unlock Higher ROI by Eliminating Rework with AI and Robotics

Rework costs construction projects billions annually, but with innovative new technologies, it doesn’t have to. By leveraging AI and robotics to replace error-prone manual tasks, contractors can virtually eliminate rework and its cascading impacts on project timelines, budgets, and profitability.

These technologies directly address the root causes of rework: inaccurate layout, tolerance stack-up, quality control gaps, labor shortages, and the fundamental challenge of maintaining manufacturing-level precision across construction-scale distances. The result is measurable savings in both time and money, with the added benefit of stronger relationships built on consistent, high-quality delivery.

For more information on how robotics can support your next project, contact Raise Robotics to start a conversation.

1 PlanRadar: The Cost of Rework in Global Construction

2 Parts Per Million (PPM) indicates the allowable error relative to the total size. A lower PPM indicates significantly higher difficulty in maintaining that precision over the full length of the object.