Manual drilling on large commercial construction sites is dangerous, physically demanding, and prone to human error. Even the most skilled workers struggle to maintain the absolute precision these projects require over long shifts, as fatigue inevitably leads to mistakes. Robotic drilling provides a safer, more accurate, and cost-effective solution. By automating repetitive drilling tasks, construction teams can dramatically reduce errors, boost productivity, and improve project ROI.

What is Robotic Drilling?

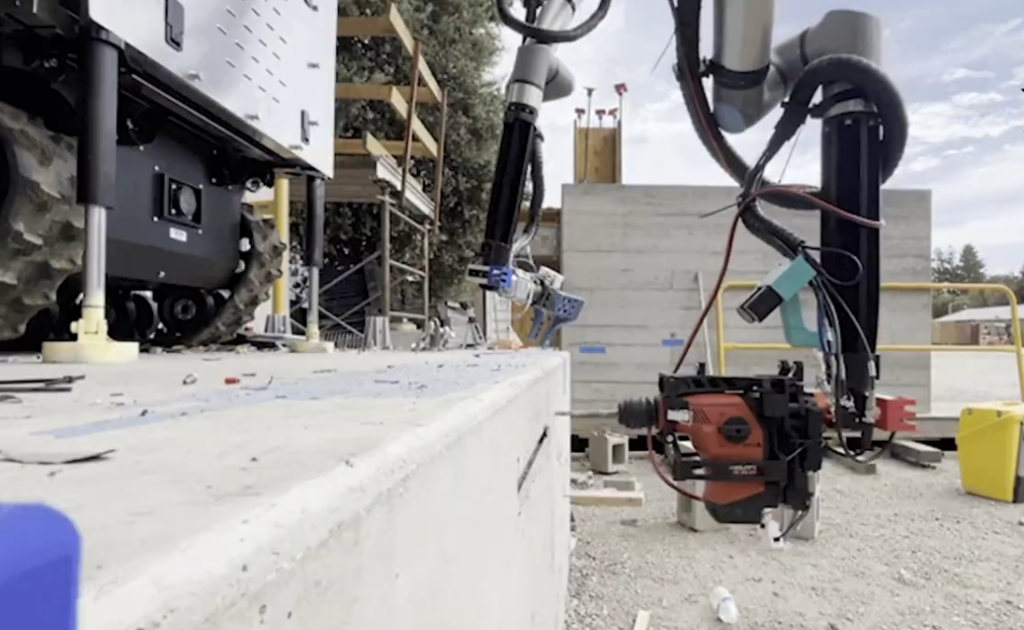

Robotic drilling uses programmable robotic systems to automate precise drilling operations on construction sites. Unlike dedicated drilling machines, robotic drilling is often performed by multipurpose construction robots equipped with specialized drilling attachments. These versatile platforms can execute complex drilling patterns with millimeter-level accuracy, then be reconfigured for other construction tasks, maximizing equipment utility and project ROI.

At its core, a drilling robot is a robotic arm connected to AI software and the project design files, which enable it to drill accurate, repeatable holes on a job site. The robot’s sensors, software, and programmed motion paths eliminate human error, fatigue, and physical strain while maintaining consistent precision throughout the day.

These automated drilling robots connect directly to project design files (CAD or BIM) and can coordinate with other tasks to avoid conflicts and optimize workflows. The integration with the project’s digital plans ensures accurate hole placement on the first attempt, eliminating costly rework and delays.

Key Components of a Drilling Robot

A sophisticated drilling robot consists of several integrated systems working together:

- The robotic arm or drilling head moves into virtually any position with extreme accuracy, guided by the project’s digital specifications.

- Advanced sensors determine when to drill, drilling depth, and when to stop, while also detecting changes in material resistance to prevent cracking and bit breakage.

- A stabilization system, consisting of clamps, deployable legs, or other mechanisms, counteracts vibrations and maintains fixed positioning during drilling operations.

- Onboard computing and software read design files, translate them into precise movements, and adapt to real-time job site conditions.

- A mobility platform with wheels or tracks enables the robot to navigate the construction site efficiently.

Autonomous and Semi-Autonomous Options

Drilling robots range from fully autonomous systems that operate independently once programmed, to semi-autonomous models that work under operator oversight for enhanced control. Depending on project requirements, robots can be configured as stationary units for concentrated work areas or mobile platforms that move throughout the site.

The Benefits of Robotic Drilling in Construction

Robotic drilling transforms construction workflows by delivering increased accuracy and efficiency, improved worker safety, and reduced labor requirements.

Delivering Precision Where It Matters Most

Precision is the cornerstone advantage of robotic drilling. Robots follow digital models exactly, eliminating common human errors in hole alignment, spacing, and depth. This accuracy translates directly into less rework and significant time and cost savings.

Advanced sensors and AI enable drilling robots to continuously assess their work, making real-time measurements and corrections as needed. The repeatability ensures each hole is drilled to exact specifications—critical for installing anchors, fasteners, MEP systems, and façade components.

Manual layout challenges like misalignment, measurement drift, and inconsistent drilling angles are virtually eliminated with robotic systems, ensuring quality remains consistent throughout the project.

Increasing Efficiency Through Automation

Drilling robots integrate seamlessly with project digital drawings and CAD models, using this data to enable precision drilling . The robot localizes to the existing environment using reference points, then uses precision positioning and autonomous movement to ensure every drill location meets digital specifications for depth, angle, and diameter.

Continuous verification processes confirm holes are drilled in proper locations, while the robot stores and transmits data to project management or quality assurance systems for real-time review and documentation.

Improving Worker Safety and Reducing Labor Burdens

Drilling large quantities of holes, especially at height, causes muscle fatigue and injury risk for human operators. Robotic drilling eliminates repetitive strain injuries from manual drilling, heavy tools, and awkward body positions. Stabilized, controlled robotic systems also minimize the risk of misfires or dangerous drill kickback.

Perhaps most importantly, robotic drilling virtually eliminates worker exposure to hazardous areas including edges, heights, and overhead drilling zones. Workers are also protected from dust and particulates generated during drilling operations. The result is improved safety and increased productivity through reduced lost-time injuries.

Labor efficiency improves as well. A single operator can manage robotic drilling operations that would traditionally require a multi-person team to perform.

Real-World Robotic Drilling Applications

Robotic drilling performs critical tasks across a variety of construction trades, including:

- Data Centers: High-volume, high-precision drilling for server rack seismic anchorage, hot/cold aisle containment systems, and overhead cable tray grids where dust control and speed are critical.

- Highway & Infrastructure: Horizontal drilling for concrete pavement dowel bars (lane widening), bridge deck repairs, and barrier wall pinning.

- Vertical Construction: Drilling thousands of anchor points per floor with consistent spacing for interior build-outs.

- MEP Installation: Precise holes for electrical conduit racks, heavy pipe hangers, and HVAC bracket mounts.

- Façade Installation: High-tolerance drilling for curtain wall anchors where post-installation adjustability is limited.

- Industrial/Retrofit: Precision work for heavy equipment installation on plant floors and structural retrofits.

Once you’ve identified your requirements, contact a robotics provider like Raise Robotics to discuss how our automated drilling robot can support your next project with precision, efficiency, and safety.

How to Choose a Construction Drilling Robot

Selecting the right robotic drilling system starts with assessing your specific project needs. Consider these key factors:

- Accuracy requirements: determines if you need a localized robot or unlocalized robot. Non-localized robots operate by showing a rough estimate of drilled location, while localized robots offer sub millimeter accuracy.

- Performance requirements: cycle times, navigation speed, uptime, communication requirements

- Operational model: Level of supervision needed (fully autonomous vs. fully -supervised systems).

- Mobility and terrain: Movement requirements based on job site conditions and layout.

- Digital integration: Compatibility with your digital assets. Does the robot require a detailed BIM model, autocad, or no digital inputs at all?.

- Power and runtime: Battery capacity or plug-in requirements for your typical work duration.

- Durability and support: Equipment ruggedness for construction environments, plus available technical support and worker training

Once you’ve identified your requirements, contact a robotics provider like Raise Robotics to discuss how our automated drilling robot can support your next project with precision, efficiency, and safety.